Many problems arise over how to properly dispose of dust in the baghouse once it is collected. Improper dust disposal can directly impact the operation of your baghouse. Storing dust in your baghouse hopper is a terrible idea. Dust collector hoppers are designed for temporary storage only. If collected dust builds up in the hopper it can cause several problems.

- It directly causes filter bag abrasion, the wearing holes near the bottoms of the bags. This happens because the rising dust levels disrupts the carefully engineered airflow mechanics within the baghouse. When high speed air is pulled across the surface of a pile of dust in the hopper it picks the dust back up (i.e. dust reentrainment) and essentially throws it back at the filter. The effect is much like sandblasting your filter bags, something no bags will ever be able to withstand.

- Large amounts of dust can provide ample fuel for fires or even combustible dust explosions. Sparks and embers can make their way into the unit from cutting, grinding or other friction generating processes as well venting of furnaces and other heat sources. These ignition sources can ignite bags upon reaching the baghouse or pass through to the hopper. In either case, large amounts of dust in the hopper provide ample fuel for continuing a fire or making it much worse.

- Excess hopper buildup will block off the baghouse and cause a loss of suction throughout the system. Loss of suction at pickup points can shutdown entire plant processes, damage equipment and even cause environmental safety hazards and increase emissions levels past permissible limits.

Clearly, failure to keep the discharge working efficiency can have serious consequences. So how can you make sure your discharge system meets the needs of your baghouse?

Get a free quote on baghouse filters!

![6 baghouse hopper dust discharge styles]() Different Baghouse Discharge Systems

Different Baghouse Discharge Systems

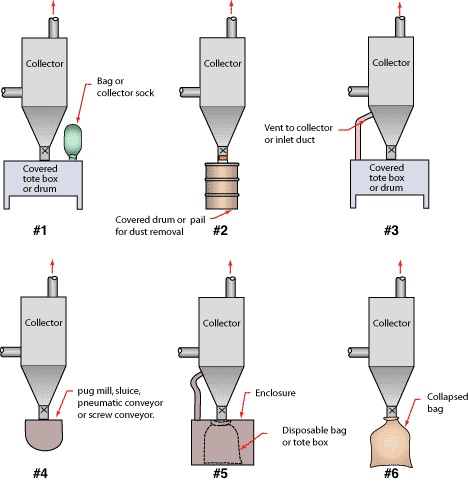

Let’s review a few common dust discharge methods and some guidelines for choosing the best option for your application.

#1, 3 – Covered Box or Drum with venting

An enclosure (usually a box or container) directly underneath the discharge holds the dust. To prevent dusting and back pressure issues the enclosure is vented by (a) a small vent with filter attached to it or (b) with a duct vent piped back to the collector or the inlet duct. Simple system, but requires maintenance to remove collected dust or else it can backup into the discharge (blocking the system) and overflow the container. Good for systems with light dust loads and nonhazardous materials.

#2, 5, 6 – Removable Storage Containers

Uses drums or bags to collect dust from discharge. When filled, technicians remove them by hand or using a forklift for disposal and then replace them with a new container. Good choice for easily handled, non-toxic dusts. Can also be useful for products that then get shipped by truck from plant (e.g. fly ash sold to cement plants, etc.) Requires technicians to monitor fill levels and replace as needed.

#4 – Discharge to conveying system

Preferred where possible, this method ensures the prompt removal of discharged dust. This proves the best solution for large units with heavy dust loads and applications requiring dust to be transported far from the collector after disposal such as hazardous material disposal, or for reuse in process. On the downside, it is more expensive than other methods and requires additional maintenance costs to maintain system.

Conclusion

We have seen that the best method of hopper discharge varies from application to application and from unit to unit. However, this does not mean that all discharge methods work for all baghouses. As outlined above, serious problems arise when the baghouse hopper discharge system is not adequate to the dust loads passing through the unit. Additionally, the disposal methods may require more man power than available at the plant and lead to spillage and other issues.

These issues can be avoided by not leaving the dust discharge method to chance. Review the operating parameters, dust loading rates, dust characteristics and eventual use of the dust (including disposal in landfill) before selecting a discharge method.

Baghouse.com has helped many plants retrofit their existing dust collectors with new hopper discharges, dust transportation and removal. Contact us today and let us advise you on how to improve your discharge system and thereby improve your dust collector efficiency today!

Need Help With Your Hopper Discharge?

Baghouse.com has helped many plants retrofit their existing dust collectors with new hopper discharges, dust transportation and removal. Contact us today and let us advise you on how to improve your discharge system and thereby improve your dust collector efficiency today!

Different Baghouse Discharge Systems

Different Baghouse Discharge Systems